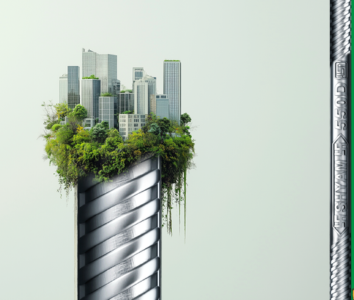

Ever wondered what keeps massive bridges, towering skyscrapers, and sprawling expressways standing tall for decades? While the design and concrete matter, the real unsung hero behind these structures is the TMT bar.

From cityscapes to coastal highways, TMT bars—short for Thermo-Mechanically Treated bars—form the skeletal system of infrastructure, offering the reinforcement needed to handle everything from heavy traffic to seismic shifts.

Let’s dive into why TMT bars are vital in the world of modern construction and infrastructure.

H2: What Are TMT Bars, and Why Do They Matter?

TMT bars are high-strength reinforcement bars with a tough outer surface and a softer core. They go through a special thermomechanical treatment that involves quenching, self-tempering, and atmospheric cooling.

Why they’re a game-changer:

- Provide superior bonding with concrete

- Resist corrosion, making them ideal for coastal and damp areas

- Sustain high loads and stress, which is critical for large-scale projects

- Exhibit excellent bendability and weldability

So, whether you’re building a highway overpass or a metro rail pillar, TMT bars form the core framework that holds the structure together.

H2: How TMT Bars Are Powering Infrastructure Across India

Infrastructure development in India is booming. From metro networks to smart cities, durable building materials are at the centre of it all.

Here’s how TMT bars support key sectors:

1. Bridges and Flyovers

For long-span structures, material fatigue and environmental exposure are major concerns. TMT bars help mitigate those issues thanks to their ability to withstand tension and compressive stress over time.

2. High-Rise Buildings

With urbanization on the rise, vertical construction is the norm. TMT bars offer the necessary reinforcement to keep high-rise structures stable and safe during wind pressure and seismic activity.

3. Dams and Power Plants

In hydro projects, structural integrity is non-negotiable. TMT bars are often used in foundation reinforcement to provide long-term reliability under immense pressure.

4. Roads and Expressways

Substructures like retaining walls, culverts, and underpasses rely heavily on reinforcement. TMT bars are used here to maintain integrity under dynamic loads.

H2: Key Benefits of Using TMT Bars in Construction

Let’s break down the core benefits that make TMT bars a must-have for infrastructure projects:

Strong Reinforcement

TMT bars provide excellent tensile strength, allowing structures to bear heavy loads without cracking or collapsing.

Longevity

TMT bars are made to last. Their resilience to environmental stress makes them ideal for infrastructure that needs to endure for decades.

Earthquake Resistance

Due to their flexibility and strong bond with concrete, TMT bars offer better performance in seismic zones.

Corrosion Resistance

TMT bars are treated to resist moisture, making them ideal for bridges, flyovers, and marine structures.

Cost-Efficient

Though the initial cost might be slightly higher, their durability and low maintenance requirements make TMT bars a cost-effective solution in the long run.

H2: Choosing the Right Grade of TMT Bars

TMT bars come in various grades—like Fe 415, Fe 500, Fe 550, and Fe 600—each suited for different applications.

Here’s a quick guide:

- Fe 415: Used for small-scale residential buildings

- Fe 500: Standard choice for general infrastructure projects

- Fe 550/600: Ideal for industrial structures, bridges, and high-rise buildings

Pro Tip: Always consult with your civil engineer or structural designer to choose the appropriate grade for your project.

TMT Bars vs Traditional Reinforcement

Wondering why TMT bars are preferred over traditional bars? Here’s a snapshot:

| Feature | TMT Bars | Traditional Reinforcement |

| Corrosion Resistance | High | Low |

| Strength | High Tensile | Moderate |

| Earthquake Resistance | Excellent | Average |

| Ductility | High | Low |

| Cost Over Time | Low Maintenance | Higher Repairs |

MS Handrails and TMT Bars – A Complementary Duo

In construction, TMT bars may form the core, but MS handrails offer the finishing safety touch. Whether it’s staircases in commercial buildings or railings along flyovers, MS handrails provide much-needed safety while seamlessly integrating with reinforced structures.

When used together, they enhance both the functionality and safety of the infrastructure.

How to Ensure Quality in TMT Bars

Buying TMT bars? Don’t just go by price. Here’s how to verify quality:

- Look for ISI certification

- Check for uniform rib pattern

- Verify manufacturer’s test certificates

- Confirm compliance with BIS standards

Always source your TMT bars from reputed suppliers known for consistency and reliability.

Final Thoughts:

Building India’s Future, One TMT Bar at a Time

From highway expansions to urban skylines, TMT bars are the hidden champions making it all possible. Their unmatched performance in terms of strength, longevity, and adaptability makes them indispensable in today’s infrastructure landscape.

So, whether you’re a contractor, builder, or a government agency planning a large-scale development, choosing the right TMT bars is an investment in safety, performance, and sustainability.

Recent Comments