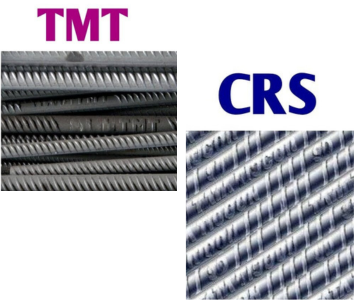

Choosing the right material for your construction project is critical. This article dives deep into the TMT Bars vs. CRS Steel debate, comparing their properties, uses, and benefits to help you make the best decision for long-lasting and durable construction.

TMT Bars vs. CRS Steel: Which Is Better for Your Construction Needs?

When it comes to construction, strength and durability are non-negotiable. The foundation of any structure relies on the materials used, and among the top contenders in the world of construction are TMT Bars (Thermo-Mechanically Treated Bars) and CRS Steel (Corrosion-Resistant Steel).

Both materials are popular for their unique properties, but choosing between TMT Bars vs. CRS Steel can be challenging, especially when factors like cost, strength, and corrosion resistance come into play.

In this detailed guide, we’ll explore the difference between TMT Bars vs. CRS Steel, their advantages, and which one is better suited for your construction needs.

What Are TMT Bars?

TMT Bars (Thermo-Mechanically Treated Bars) are high-strength reinforcement bars widely used in construction. These bars are processed with heat treatment, which gives them a tough outer layer and a softer inner core. This combination ensures durability, flexibility, and high tensile strength.

Key Features of TMT Bars:

- High Tensile Strength: Can withstand heavy loads without breaking.

- Ductility: The soft inner core provides flexibility, making it ideal for earthquake-prone zones.

- Corrosion Resistance: Advanced manufacturing ensures that TMT Bars resist rust, even in humid environments.

- Weldability: Easy to weld without losing strength or structural integrity.

Applications of TMT Bars:

- Reinforcement in concrete structures like beams, columns, and slabs.

- Infrastructure projects like bridges, dams, and highways.

- Residential and commercial buildings.

What Is CRS Steel?

CRS Steel, or Corrosion-Resistant Steel, is specifically designed to combat corrosion. It contains alloying elements like chromium, copper, and nickel that enhance its ability to resist rust and withstand harsh environmental conditions. CRS Steel grades are commonly used in projects that require extra protection from moisture, chemicals, or saline water.

Key Features of CRS Steel:

- Corrosion Resistance: Can withstand exposure to water, chemicals, and saline environments.

- High Strength: Offers excellent load-bearing capacity.

- Durability: Maintains structural integrity over extended periods, even in challenging conditions.

- Versatility: Available in different CRS steel grades to suit varying project requirements.

Applications of CRS Steel:

- Coastal and marine construction.

- Industrial plants exposed to chemicals.

- High-rise buildings in humid or saline environments.

TMT Bars vs. CRS Steel: Key Differences

Both TMT Bars and CRS Steel have unique properties, but their suitability depends on the nature of your construction project. Let’s explore the difference between TMT Bars vs. CRS Steel in detail:

| Feature | TMT Bars | CRS Steel |

| Material Composition | Low carbon steel with a heat-treated outer layer. | Steel with alloying elements like chromium and copper. |

| Corrosion Resistance | Resistant to rust due to advanced manufacturing techniques. | Highly corrosion-resistant, ideal for harsh environments. |

| Strength | High tensile strength and flexibility. | Strong with enhanced rust resistance. |

| Applications | Ideal for reinforcement in concrete structures. | Best for coastal, industrial, and marine projects. |

| Cost | More affordable for general construction. | Slightly expensive due to alloying elements. |

| Environmental Suitability | Suitable for most environments. | Best for humid, saline, or chemical-prone areas. |

Quick Tip:

For standard residential or commercial construction, TMT Bars offer the perfect balance of strength and affordability. If you’re building in coastal or industrial areas, CRS Steel is worth the extra investment due to its superior corrosion resistance.

TMT Bars vs. CRS Steel: Pros and Cons

Pros of TMT Bars:

- High Tensile Strength: Ensures long-lasting structures.

- Cost-Effective: More affordable compared to CRS Steel.

- Ductility: Flexible and ideal for seismic zones.

- Rust Resistance: Resists corrosion to a large extent.

Cons of TMT Bars:

- Limited in Saline Environments: While corrosion-resistant, they may not last as long as CRS Steel in marine conditions.

- Requires Protective Coating: For long-term rust resistance in extreme conditions.

Pros of CRS Steel:

- Unmatched Corrosion Resistance: Performs exceptionally well in humid, coastal, and chemical-prone areas.

- Durability: Can withstand harsh environmental conditions for years.

- Versatility: Available in multiple grades to meet specific project needs.

Cons of CRS Steel:

- Higher Cost: The inclusion of alloying elements makes it more expensive.

- Specialized Use: Not cost-effective for standard construction projects.

When to Use TMT Bars vs. CRS Steel

Choose TMT Bars If:

- You’re constructing residential or commercial buildings in standard environments.

- Your project is in an earthquake-prone zone, as TMT Bars offer excellent ductility.

- You’re looking for a cost-effective solution without compromising on strength.

Choose CRS Steel If:

- Your project is in a coastal, industrial, or chemical-heavy area where corrosion resistance is critical.

- You’re working on marine structures like ports, ships, or docks.

- Long-term durability in harsh environments is your top priority.

CRS Steel Grades: Explained

CRS Steel Grades define the level of corrosion resistance based on the percentage of alloying elements like chromium and copper. Common grades include:

- Grade 1: Ideal for environments with mild corrosion risks.

- Grade 2: Best for moderately corrosive environments.

- Grade 3: Recommended for highly corrosive areas like marine or industrial zones.

Pro Tip:

Consult your supplier or structural engineer to determine the appropriate CRS steel grade for your specific project requirements.

FAQs

1. Which is better, TMT Bars or CRS Steel?

It depends on your project. TMT Bars are excellent for general construction, while CRS Steel is better for projects exposed to moisture, chemicals, or saline environments.

2. Are TMT Bars corrosion-resistant?

Yes, TMT Bars offer rust resistance, but CRS Steel provides superior protection against corrosion in extreme conditions.

3. What are CRS Steel grades?

CRS Steel grades indicate the level of corrosion resistance. Higher grades are better suited for harsh environments like coastal or industrial areas.

4. Can CRS Steel be used in place of TMT Bars?

CRS Steel is not typically used as a replacement for TMT Bars in reinforcement. They serve different purposes but can complement each other in specific scenarios.

5. Are TMT Bars cost-effective?

Yes, TMT Bars are more affordable than CRS Steel, making them ideal for standard construction projects.

Final Thoughts: Choosing the Right Material

In the TMT Bars vs. CRS Steel debate, the decision boils down to your project’s specific requirements. If you’re building in standard conditions, TMT Bars provide the perfect combination of strength, flexibility, and affordability. However, for projects in coastal, marine, or chemical-heavy environments, CRS Steel offers unmatched corrosion resistance and long-term durability.

When selecting materials, don’t just consider the cost—factor in longevity, environmental conditions, and maintenance requirements. Choosing the right material ensures the safety and stability of your structure for years to come.

Contact Us for Expert Advice!

Need help choosing between TMT Bars and CRS Steel?

📍Address: Plot No: A-3, Nagar-Pune Road, Supa Parner Industrial Area, Supa, Parner, Ahmednagar – 414003.

📞Phone: +91 9766173352

📧Email: sales@ganrajispat.com

🌐Website: www.pushpasteel.com

Let us guide you in selecting the best material for your construction needs!

Recent Comments